WOW

that is amazing!! that titan is increadble but the titan killer!!!! WOW

you are amazing sir

(are you chuck noriss of 40k ? or the emperor)

BoLS Lounge : Wargames, Warhammer & Miniatures Forum

Results 11 to 20 of 154

-

04-19-2010, 10:19 AM #11

visit my blog: www.fuzzbuket.blogspot.com I do cheap commsion work

visit my blog: www.fuzzbuket.blogspot.com I do cheap commsion work

And COME TO BOLSCON UK and yell about my font!

-

04-19-2010, 01:36 PM #12

i dont know???? it could be a fw one modded a bit. something in me is saying this isnt real. but then it may well be...

currently working on a line of sci-fi bunkers and tunneling, input always appreciated

-

04-19-2010, 06:32 PM #13

This should be interesting, in all the forums I've posted no one has doubted the veracity of the claim of "scratch build". Lucie is entirely made of plasticard over a foam core posterboard but I suppose I should begin at the beginning:

About a year and a half ago I was finishing up the 'Titan Hunter' (It will be the subject of another thread if anyone has an interest) and I was discussing with my son what to do for the next project and he said the Apocalypse rules allow for Warhounds in the game so we decided on a Lucius Warhound for a project.

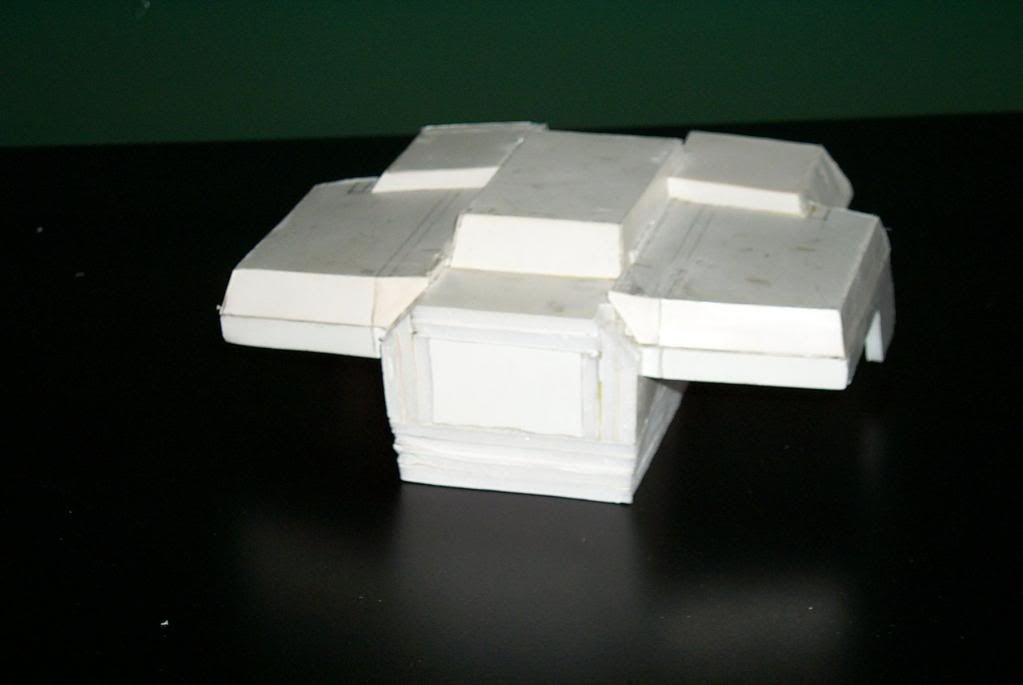

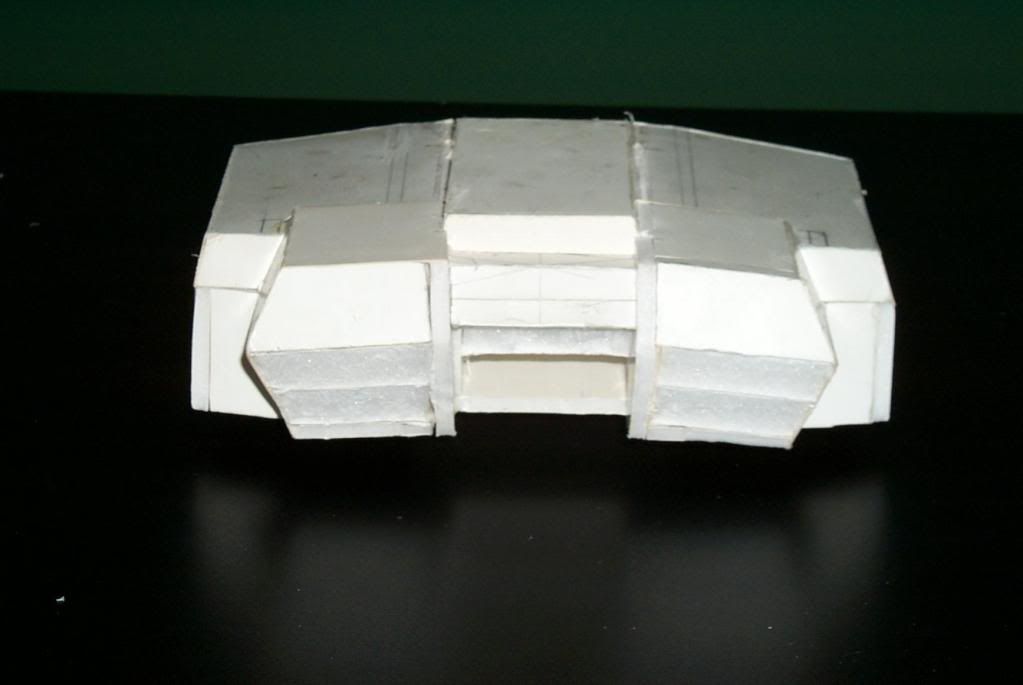

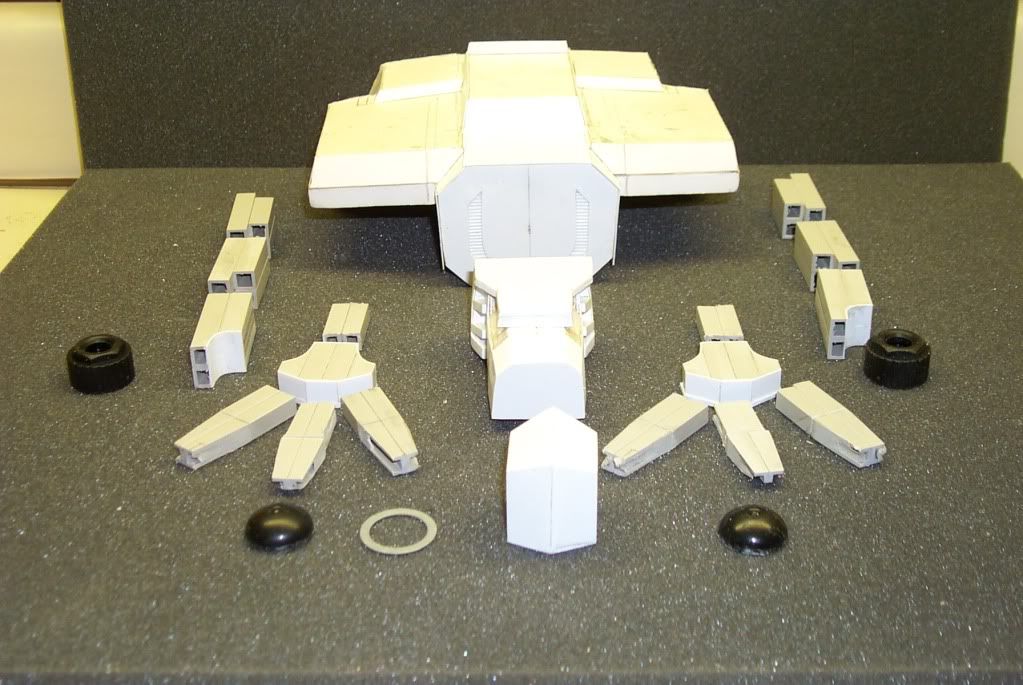

I started this project in March 09 and after a few failed starts last year I final made a body core that was of a reasonable shape and size. It was a very inauspicious beginning. At that time I had no idea what size an actual Warhound was other than the cryptic statement that the model stands 10.5" high. Well considering that you can build it in a lot of different poses "10.5 inches" is not much to go on. I had hundreds of images I had found on the web but not one gave a hint as to any measurement. Blindly I started to make a hull out of foam board just to get a feel for the construction.

This pitiful assembly is still at the core of Lucie.

Blackadder

-

04-19-2010, 06:34 PM #14

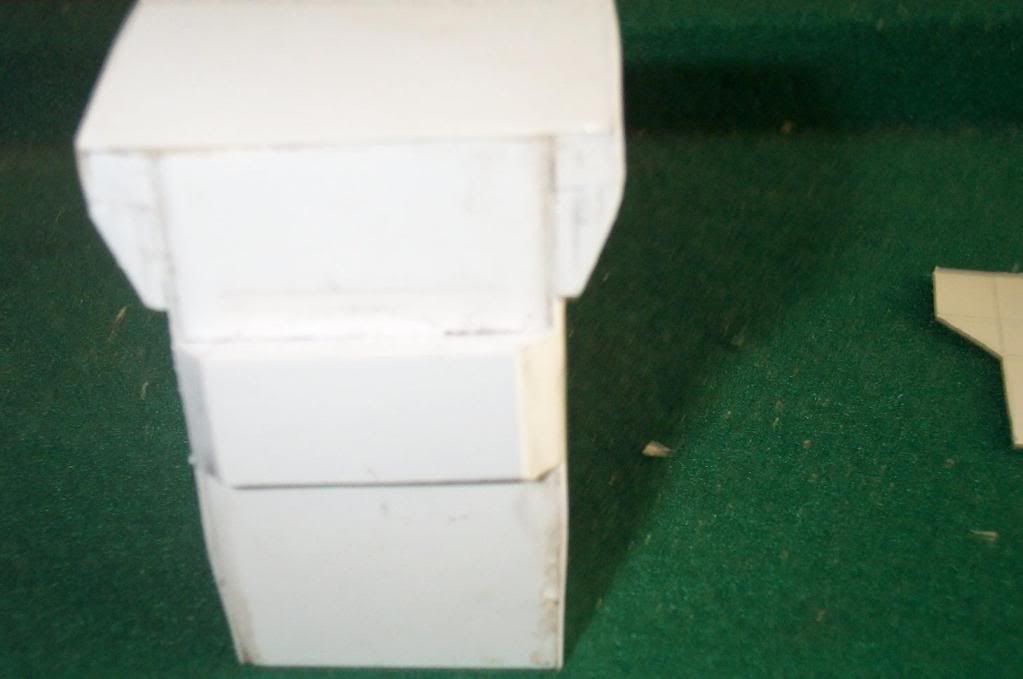

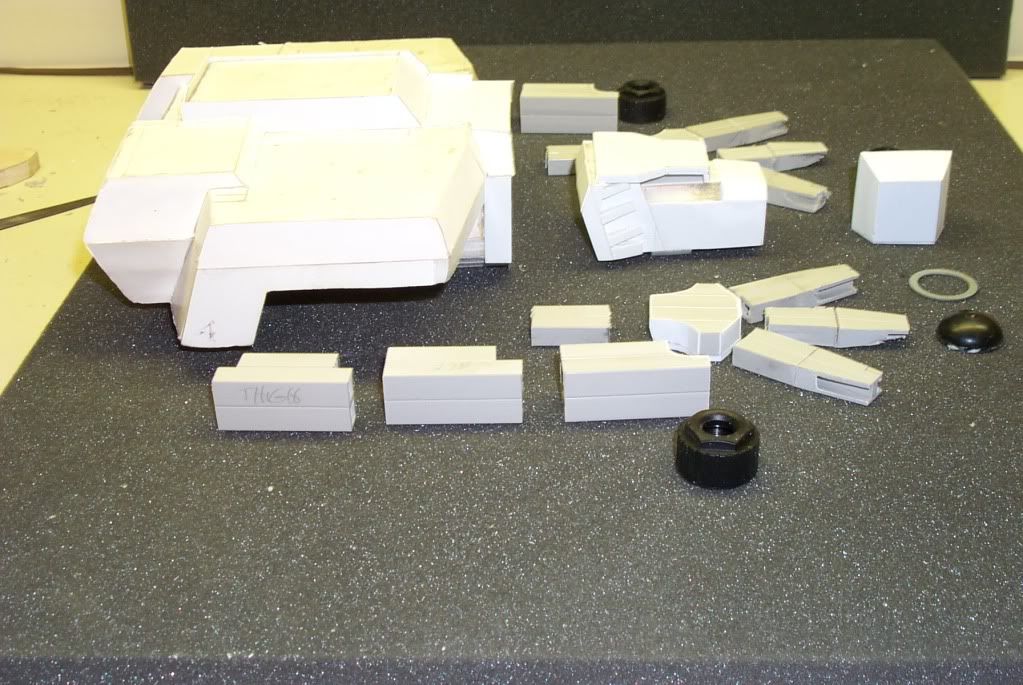

I have very few images of the initial construction as I was out looking for a new career.

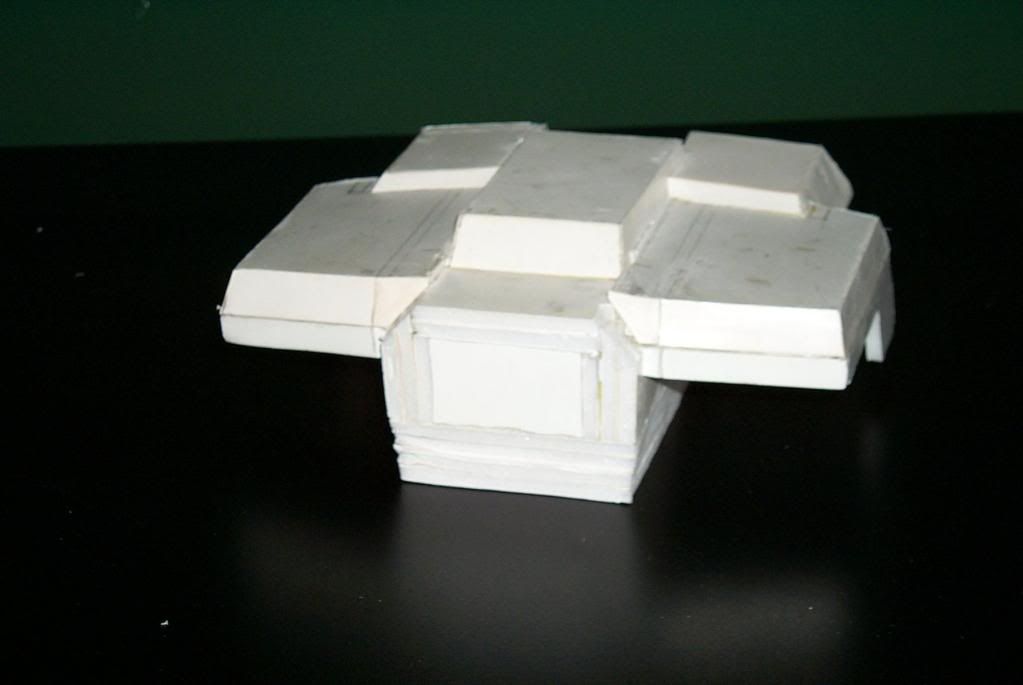

Here are the first few construction images. I decide on foam core posterboard for the hull and carapace because heavier material would make Lucie top heavy especially with the pivot point so far aft. Too far aft as I found out later and the waist pivot point has been brought further forward about three times to it's current location.

See, All too human. LOL

Sorry to say my documentation of the preliminary parts were very sparse.

EB

-

04-19-2010, 06:36 PM #15

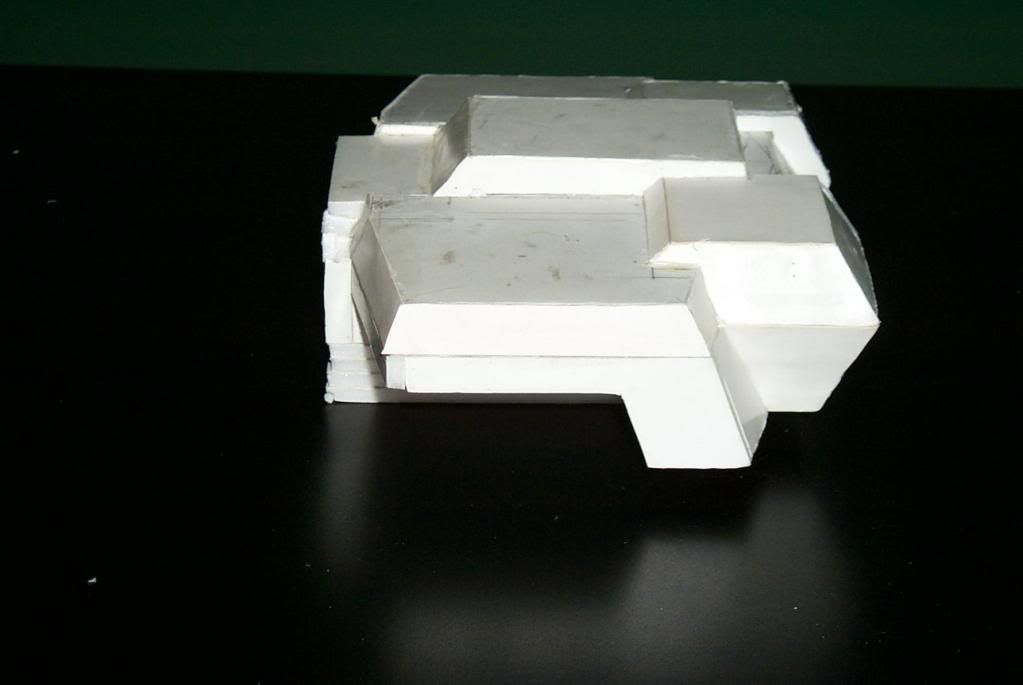

One week into the build and I was still feeling my way along as far as size and proportion. Surprisingly the hull and carapace I had nailed from the beginning. I have not had to change anything on either other than to skin them with plasticard.

-

04-19-2010, 06:37 PM #16

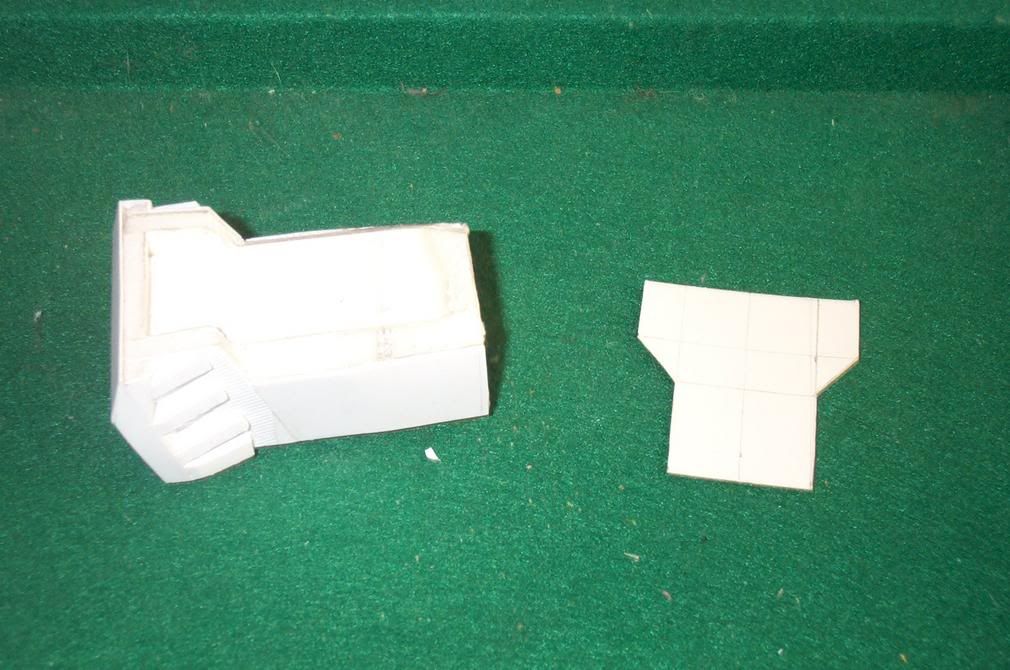

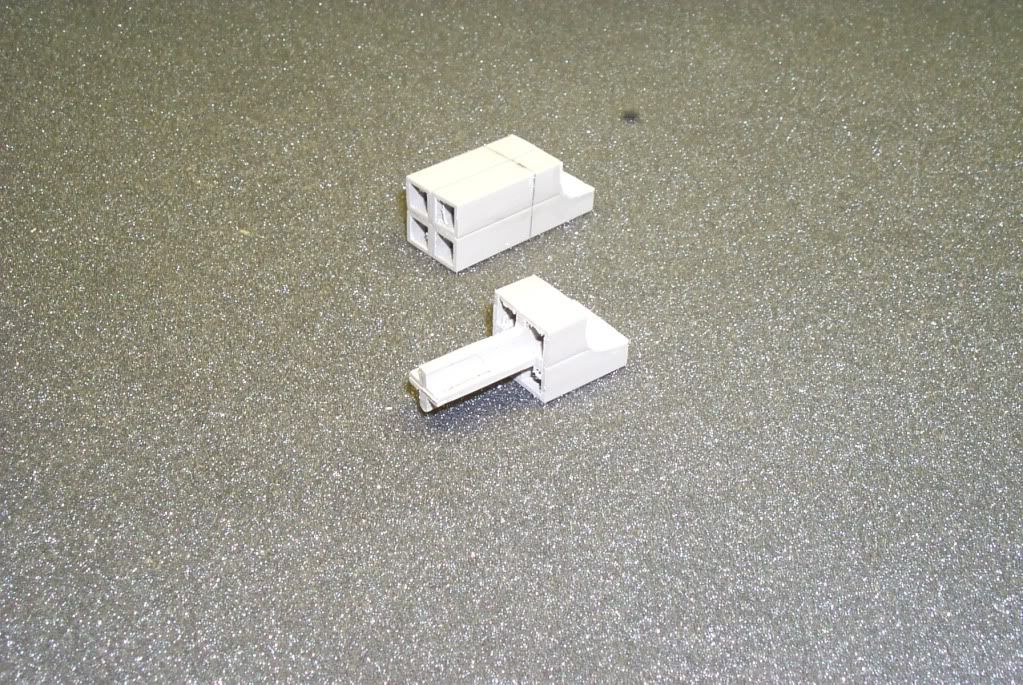

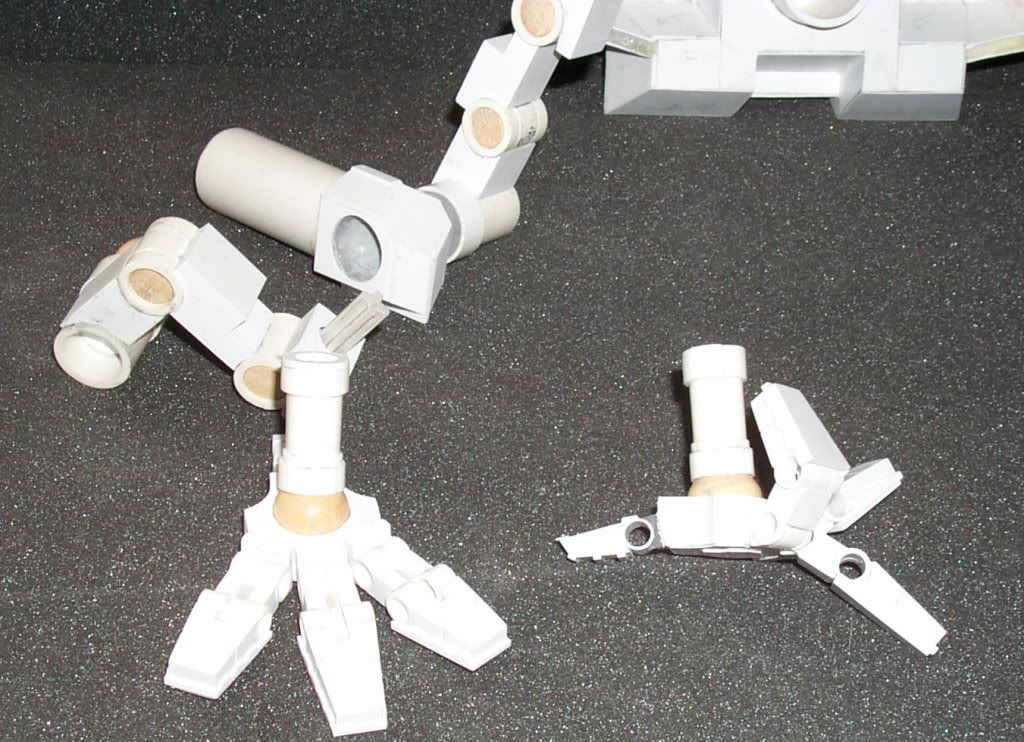

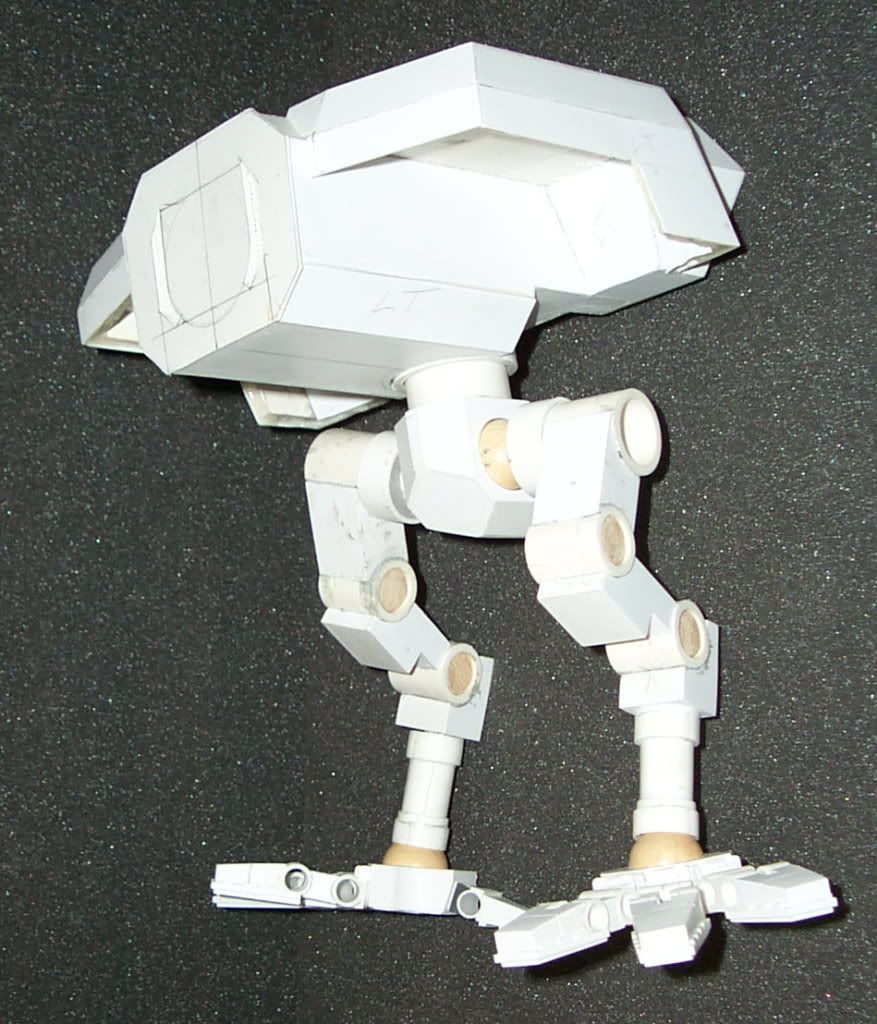

The legs were another story. My first set were functional but too small and dainty.

I might add at this time I wasn't going to copy the FW model exactly but the cardboard model the plans of which that are floating around the web.

After I assembled the various components I thought, "I can do better."

A that point the madness commenced,

E.B.Last edited by Blackadder; 04-20-2010 at 02:00 AM.

-

04-19-2010, 06:39 PM #17

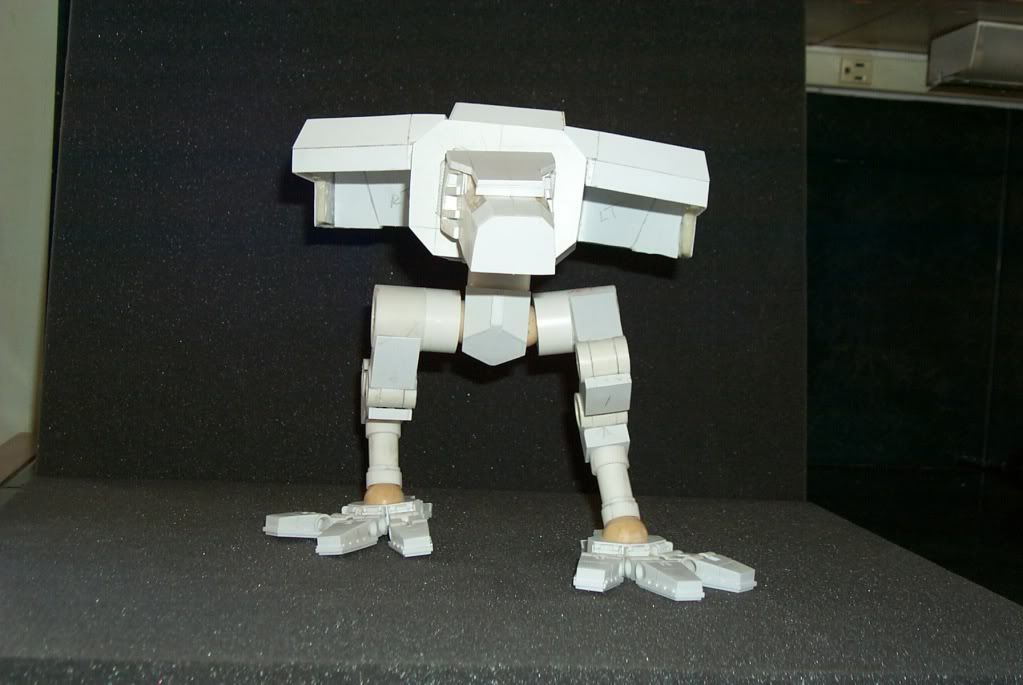

I was none too gently apprised that the legs were not robust enough and I hastily scraped the leg work and rebuilt them in a grander scale. These seemed to fit the bill and I proceeded with the over all build.

At that time little did I know that I had built in some ill reconcilable flaws that would come to haunt me later on and almost caused me to scrap the project.

The following pictures I call:

"Then a Miracle Happened"

as I have no intervening photographs! LOL

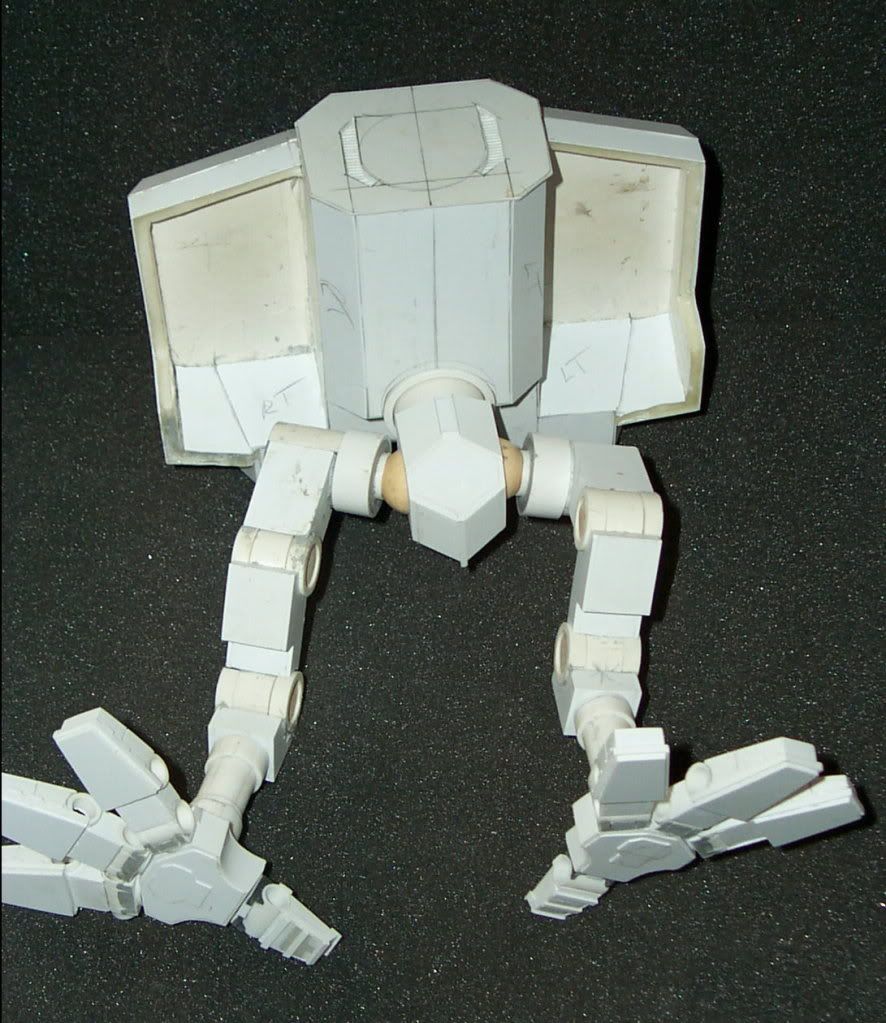

A very gratifying photo of Lucie when I first assembled all the components. An error in perception prevented me from noting the obvious mistakes pleased as I was with the overall look.

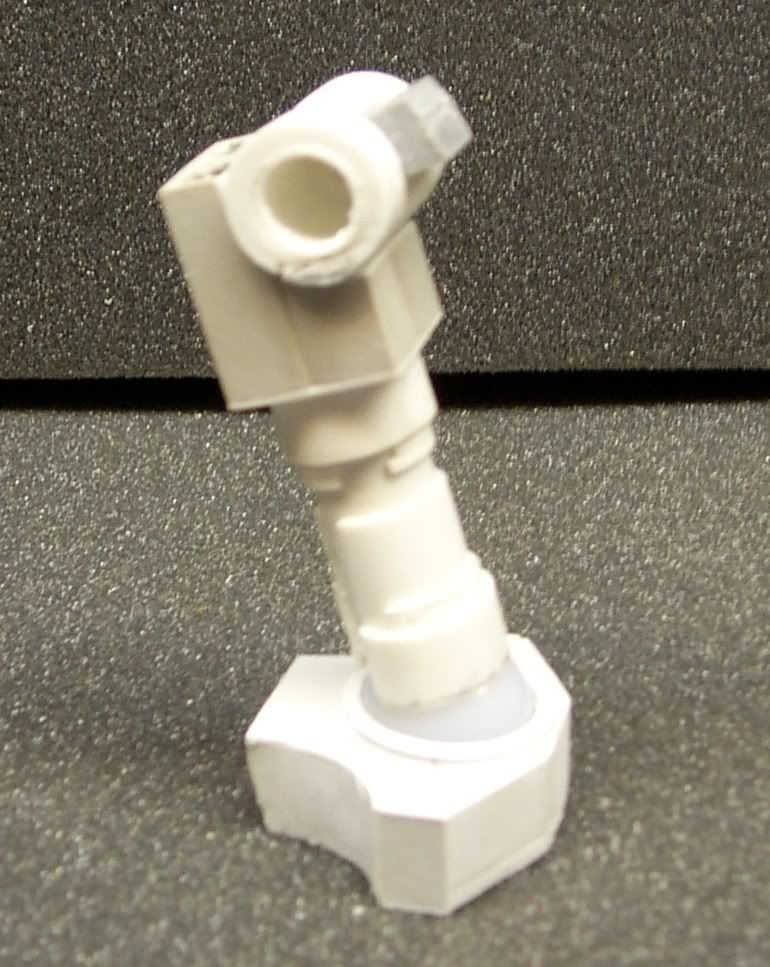

Even at this early stage I knew I wanted Lucie pose-able. I worked towards that goal using PVC plumbing pipe and wood dowels for the axles on the legs and the marvelous properties of Evergreen telescoping styrene tubing for the toes. Note the amount of flexing the toes initially had. The hydraulic cylinders designed by FW severely restricted the actual amount of movement the finished toes could make. Were it not for the cylinders in the toes and legs Lucie would be much more pose-able.

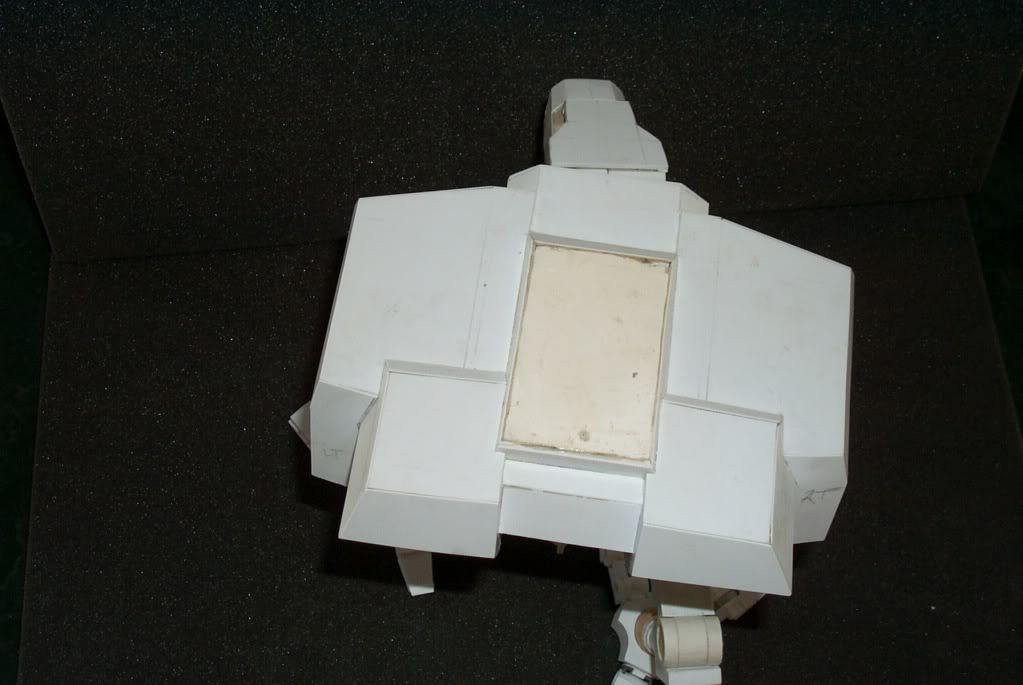

This extremely undignified pose highlights all the flaws that almost caused me to quit. The waist is too far aft on the hull, The waist itself is far too small. The upper leg segments are too long and not robust enough, The hip axles and hydraulic mounting cylinders are too small in diameter and the toes are too long!

Happily I circumvented these problems but it did cause me to add a month or two to the actual construction. I spent weeks deciding whether to rebuild the offending mistakes or just finish it up half-assed and hide it from the world.

It pays to work off of plans boys and girls, I'll never do another project I haven't any scale drawings for.

Blackadder

-

04-19-2010, 06:43 PM #18

In my last post I intimated that I was apprised the legs were too delicate looking for the body. Absolutely correct and I scrapped 90% of the work I had done on the legs. Fortunately the new dimensions brought me up to the PVC pipe range which made the joints easier to fabricate. I kept the hull and covered it with .05" Evergreen styrene plastic card sheeting. There is a commercial 7 minute epoxy made for plastic and it is wonderful stuff. It even adheres plastic to card stock.

I'll go into greater detail of the construction but first a picture to see if my effort meets your approval.

Blackadder

-

04-19-2010, 06:47 PM #19

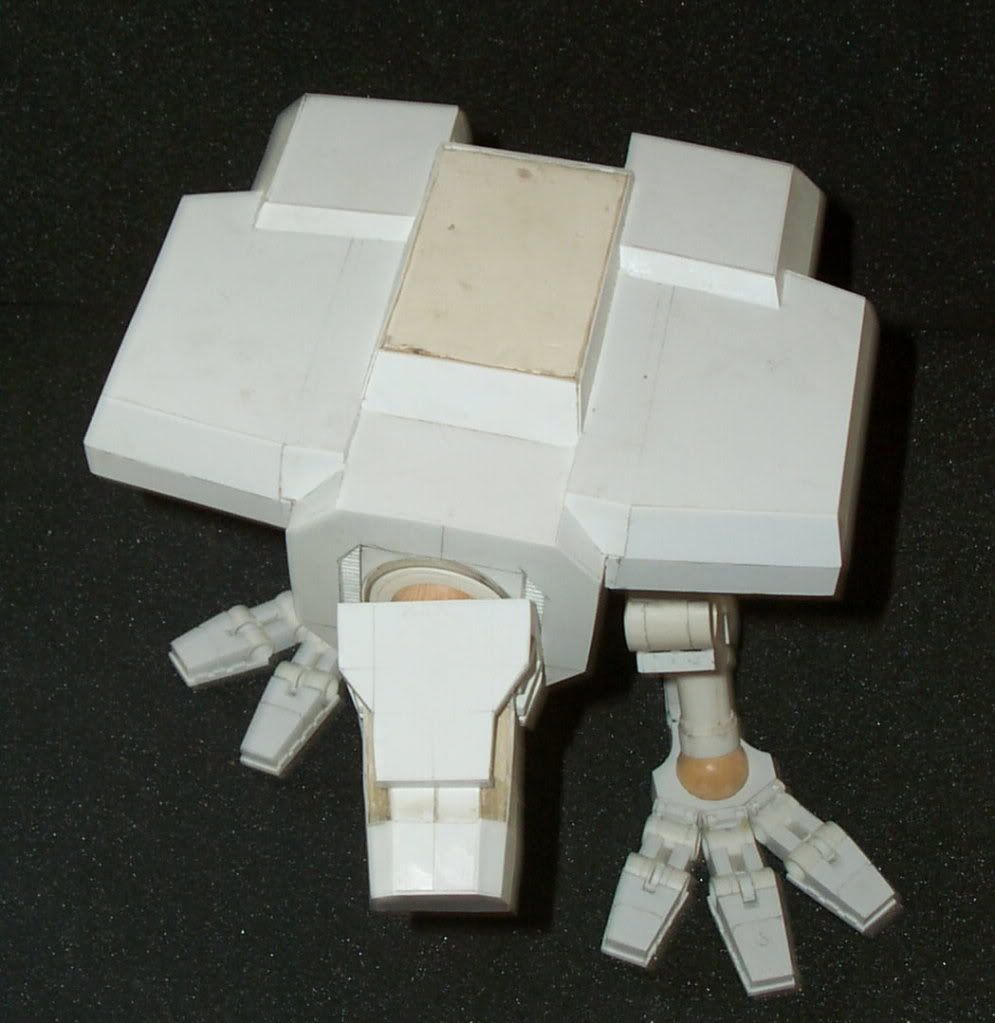

One picture is worth a thousand words and in this case a thousand errors of perception. Working without any plan or measurement I had made numerous errors in scale and one digital photo revealed them. So after an all night rebuild here is the result plus I managed to attach the head as well. All the leg and hip joints including the feet and toes are fully movable and pose-able at this point and I made the neck connection movable as well. Try that one FW

Last edited by Blackadder; 04-22-2010 at 02:04 PM.

-

04-19-2010, 06:48 PM #20

Whew,

E. Blackadder

Constructive critiques and comments would be greatly appreciated,

EBLast edited by Blackadder; 04-22-2010 at 02:36 PM.

Reply With Quote

Reply With Quote